Top Essay Writers

Our top essay writers are handpicked for their degree qualification, talent and freelance know-how. Each one brings deep expertise in their chosen subjects and a solid track record in academic writing.

Simply fill out the order form with your paper’s instructions in a few easy steps. This quick process ensures you’ll be matched with an expert writer who

Can meet your papers' specific grading rubric needs. Find the best write my essay assistance for your assignments- Affordable, plagiarism-free, and on time!

Posted: October 3rd, 2022

Contents

We hear “Can you write in APA or MLA?” all the time—and the answer’s a big yes, plus way more! Our writers are wizards with every style—APA, MLA, Harvard, Chicago, Turabian, you name it—delivering flawless formatting tailored to your assignment. Whether it’s a tricky in-text citation or a perfectly styled reference list, they’ve got the skills to make your paper academically spot-on.

Procedure 1 (Viscosity varying temperature)

Procedure 2 (Varying sheer stress) (Ketchup and Mayonnaise)

Procedure 3 (Viscosity varing shear rate)(cornstarch)

Yes, completely! They’re a valid tool for getting sample papers to boost your own writing skills, and there’s nothing shady about that. Use them right—like a study guide or a model to learn from—and they’re a smart, ethical way to level up your grades without breaking any rules.

Prices start at $10 per page for undergrad work and go up to $21 for advanced levels, depending on urgency and any extras you toss in. Deadlines range from a lightning-fast 3 hours to a chill 14 days—plenty of wiggle room there! Plus, if you’re ordering big, you’ll snag 5-10% off, making it easier on your wallet while still getting top-notch quality.

Calibration of Rheometer – The hazard that would cause the biggest issues for the system are the pinch points in the rheometer as large pressure is applied to the system and operators that are not aware of the danger may gain injuries due.

Adjustment of Spindles – The spindles offer light hazards as they may cause small injuries as there are tight points that need to be adjusted for the spindles. These spindles need to be adjusted by hand meaning proper care should be taken in to account to ensure the spindles are secure as they will be moving.

Maintaining of Constant temperature – The system using heating equipment, but the system is full enclosed meaning there is a low chance of burns. The system will be used between the temperatures of 15-30°C. The main danger is the system being used poorly as an operator might set the temperature too hot or the water not being in the system and the heating wire burning out.

Nope—your secret’s locked down tight. We encrypt all your data with top-tier security, and every paper’s crafted fresh just for you, run through originality checks to prove it’s one-of-a-kind. No one—professors, classmates, or anyone—will ever know you teamed up with us, guaranteed.

Compressing of Fluids – Rheometer acts at large shear rates could cause injury to an operator’s hand if they are pressed close to the user because of this any operator should keep a safe distance when the apparatus is turned on.

Rotation of Spindle – The spindle will rotate in a glass beaker which may cause injury to a person’s hands or by damaging equipment. As is usual with equipment rotating quickly there is a very dangerous hazard of loose clothing and hair being caught up in the machine to reduce this regular laboratory grooming procedure should be followed.

Electrical Apparatus – The wires in the apparatus are mostly insulated but could be damaged if any damage is seen it should be reported to a laboratory attendant as in the experiment water will be used to make up solution and could be very dangerous if this hazard is ignored.

Moving around the lab – General hazards around the laboratory such as slips trips and fails. These are the most common injuries, Theses can be avoid by practicing good house-keeping around the laboratory by keeping the work space clean.

Not even a little—our writers are real-deal experts with degrees, crafting every paper by hand with care and know-how. No AI shortcuts here; it’s all human skill, backed by thorough research and double-checked for uniqueness. You’re getting authentic work that stands out for all the right reasons.

Using Glass Equipment – Glass beakers are used, any breakage of material should immediately clean and placed in the designated glass bin in the back of the laboratory. With lab equipment such as glass the hazards tend to be cause in series as if a beaker breaks it may cause a spillage of the material it was holding if this happens the material should be immediately cleaned before carrying on with the experiment.

The objective of this experiment is to measure the viscosity of certain fluids and test the affect that shear rate has on them. The fluids that are to be tested in this experiment are ketchup, mayonnaise and a corn starch solution. The reason that a corn starch solution is to be tested is that at higher concentrations of corn starch in water the solution can react very Non-Newtonian. A different measurement device will have to be used for this solution. The solution of corn starch in question is a 50% w/w solution of corn starch and water.

Figure 1 – Ketchup and Mayo to be used in experiment (Elite Daily, 2018)

Our writers are Ph.D.-level pros who live for nailing the details—think deep research and razor-sharp arguments. We pair that with top plagiarism tools, free revisions to tweak anything you need, and fast turnarounds that don’t skimp on quality. Your research paper won’t just shine—it’ll set the bar.

The samples of the mayonnaise and ketchup will be placed on the plate of the Brookfield’s Rheometer in the lab and the corn starch solution will be placed in a beaker with the spindle from the Brookfield’s Viscometer inside it.

There are two different pieces of equipment being used in this experiment. The first one is the Brookfield Rheometer which will be used for the less viscos fluids stated above. The plate can be heated, and different shear rates can be applied to the plate. Both properties of this piece of equipment allow the rheologic properties of the materials to be acquired.

Figure 2 – Brookfield’s Rheometer (News Medical Life Sciences, 2018)

You’re in good hands with degree-holding pros—many rocking Master’s or higher—who’ve crushed our tough vetting tests in writing and their fields. They’re your partners in this, hitting tight deadlines and academic standards with ease, all while tailoring every essay to your exact needs. No matter the topic, they’ve got the chops to make it stellar.

The second piece of equipment to be used is the Brookfield’s Viscometer. This is the device used to calculate the viscosity of the corn starch solution. The device can be calibrated by navigating through the simple menus on the panel of the device where the rpm and other parameters are set. Using this the shear rate of the corn starch can be calculated and then compared with the values from the other device.

Figure 3 – Brookfield’s Viscometer (Amazon, 2019)

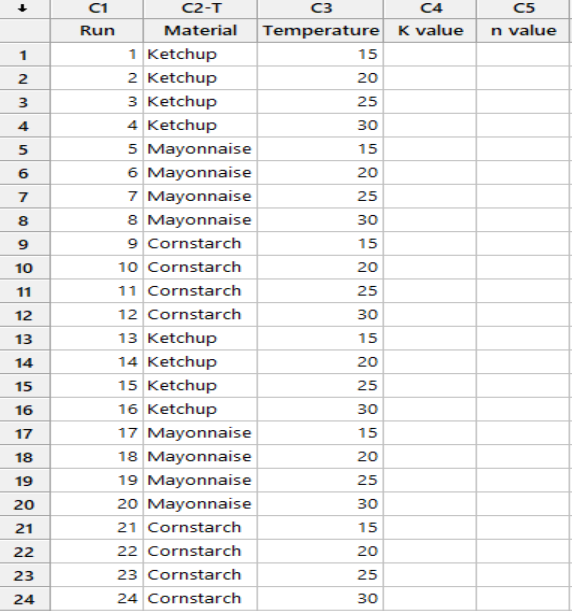

The design of this experiemwnt will be used to determine with a 95% confidence interval wether of not changing the material will effect the viscosity of the materials of ketchup, mayonnaise and cornstarch. The materials are measure between the temperatures between the values of 15-30°C. The will be two replicantes for the system to ensure better results. The K value and n values for the system can be compared to see the classfication of the materials used.

100%—we promise! Every paper’s written fresh from scratch—no AI, no copying—just solid research and proper citations from our expert writers. You can even request a plagiarism report to see it’s 95%+ unique, giving you total confidence it’s submission-ready and one-of-a-kind.

Table 1 – Changing viscosity with temperature of materials Ketchup Mayonnaise and Cornstarch

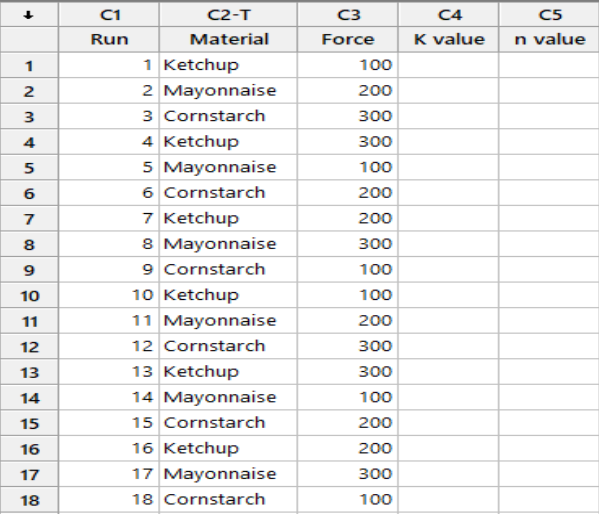

The second design of experiment the temperature is remained constant. The system that is being tested is does material effect the effect of the viscosity on sheer stress with a 95% confidence level. There are two replicates for the system. The system is testing the system under the sheer stress rates of 100,200 and 300 (1/s). The is a large error in the system as the corn-starch solution is too difficult to measure in the same instrumentation as the ketchup and mayonnaise so it is measure separately in a beaker. The instrumentation should be properly calibrated making the values with 5% of there true value making the error much smaller.

Table 2 - Showing the Material (A) Force (B) for ketchup mayonnaise and cornstarch on Minitab

For Newtonian fluids such as water, the viscosity of the substance remains constant regardless of the volume of shear stress applied. However, the viscosity of non-Newtonian fluids can increase or decrease with shear stress. In the case of tomato ketchup, the fluid remains almost solid in the bottom of the container until it is squeezed (i.e. a certain force is applied to the system) after which it easily squirts out. This phenomenon is called “shear thinning” (Chemistry World, 2011). Meanwhile, a mixture of cornstarch and water changes from fluid-like to behaving almost like a solid when additional shear is applied. This phenomenon is called “shear thickening”.

Yep—APA, Turabian, IEEE, Chicago, MLA, whatever you throw at us! Our writers nail every detail of your chosen style, matching your guidelines down to the last comma and period. It’s all about making sure your paper fits academic expectations perfectly, no sweat.

Figure 5.1.1 – Viscosity of Newtonian, Shear Thinning and Shear Thickening fluids as a function of shear rate

[Source: RheoSense, 2019]

Tomato ketchup is a two-phase system in which solid particles of tomato pulp and added spices are dispersed in a colloidal continuous phase that consists of sugars, salts, organic acids, a fraction of soluble pectins, and other compounds of extract dissolved in water. The components of the ketchup which affect the viscosity most include the thickening agents, particularly polysaccharide hydrocolloids (Gujral et. al, 2002). Guar and xanthan gums are found to be the most successful in decreasing serum separation of the fluid (Varela et al., 2003; Sahin and Özdemir, 2007). The rheological properties of ketchup are affected by the rheological characteristics of tomato concentrate (Bayod et. al, 2008; Barbana and El-Omri, 2009). Tomato variety, sieve pore sizes and the temperature of the concentration process are found to be the critical parameters which most affect the rheological characteristics (Sanchez et. al., 2002; Valencia et. al., 2004).

Absolutely—life happens, and we’re flexible! Chat with your writer anytime through our system to update details, tweak the focus, or add new requirements, and they’ll pivot fast to keep your paper on point. It’s all about making sure the final draft is exactly what you need, no stress involved.

Bingham plastics are fluids which require a minimum applied stress in order to flow. Mayonnaise is one such fluid. They are strictly non-Newtonian, but once the flow starts, they behave essentially as Newtonian fluids. This mean that the shear stress is linear with the shear rate.

Concentrated cornstarch suspensions have been shown to exhibit shear thickening behaviour. This is because as the shear rate increases, the viscosity of the fluid also increases. At rest, the voidage of the suspension is at a minimum and the liquid present in the sample is sufficient to fill the voids completely. At low shearing rates, the liquid lubricates the motion of each particle past another thereby minimising solid-solid friction. Consequently, the resulting stresses are small (Chhabra, n.d.). At high shear rates, however, the mixture expands slightly so that the available liquid is no longer sufficient to fill the increased void space and to prevent direct solid-solid contacts (and friction). This leads to the development of much larger shear stresses than that seen in a pre-dilated sample at low shear rates. This mechanism causes the apparent viscosity η(= σ/γ˙) to rise rapidly with the increasing rate of shear (Chhabra, n.d.).

Figure 5.1.2 – Shear stress as a function of shear rate for several types of fluids

It’s super easy—order online with a few clicks, then track progress with drafts as your writer works their magic. Once it’s done, download it from your account, give it a once-over, and release payment only when you’re thrilled with the result. It’s fast, affordable, and built with students like you in mind!

[Source: RheoSense, 2019]

Non-Newtonian fluids flow behaviour can be best modelled using the Herschel Bulkley equation where shear stress,

is measured in mPa. This model is a three parameter yield/power law model which was developed in 1926. The model consists of two distinctive parts. The first term is the Herschel Bulkley yield stress and is denoted by

We can crank out a killer paper in 24 hours—quality locked in, no shortcuts. Just set your deadline when you order, and our pros will hustle to deliver, even if you’re racing the clock. Perfect for those last-minute crunches without compromising on the good stuff.

. The second term,

originates from de Waele and Ostwald. K is the consistency coefficient and is measured in units of Pa

For sure! Our writers with advanced degrees dive into any topic—think quantum physics or medieval lit—with deep research and clear, sharp writing. They’ll tailor it to your academic level, ensuring it’s thorough yet easy to follow, no matter how tricky the subject gets.

where n is the power law exponent. The Herschel Bulkley equation describes viscoplastic behaviour when n < 1. As the power law (i.e. where

shear thinning n < 1; shear thickening n > 1), Newtonian (i.e. where

n = 1) and Bingham plastic behaviour (i.e. n = 1) can be regarded as special cases, the model represents the flow behaviour of a wide range of fluids (Fester et al., 2012). The second term in the Herschel Bulkley equation,

We stick to your rubric like glue—nailing the structure, depth, and tone your professor wants—then polish it with edits for that extra shine. Our writers know what profs look for, and we double-check every detail to make sure it’s submission-ready and grade-worthy.

when plotted on a log-log graph models a straight line with a slope of n. Values of n typically range from 0.2 to approximately 1.4. The further the value of n is from unity, the more non-Newtonian the fluid is.

(5.1)

You Want The Best Grades and That’s What We Deliver

Our top essay writers are handpicked for their degree qualification, talent and freelance know-how. Each one brings deep expertise in their chosen subjects and a solid track record in academic writing.

We offer the lowest possible pricing for each research paper while still providing the best writers;no compromise on quality. Our costs are fair and reasonable to college students compared to other custom writing services.

You’ll never get a paper from us with plagiarism or that robotic AI feel. We carefully research, write, cite and check every final draft before sending it your way.