Top Essay Writers

Our top essay writers are handpicked for their degree qualification, talent and freelance know-how. Each one brings deep expertise in their chosen subjects and a solid track record in academic writing.

Simply fill out the order form with your paper’s instructions in a few easy steps. This quick process ensures you’ll be matched with an expert writer who

Can meet your papers' specific grading rubric needs. Find the best write my essay assistance for your assignments- Affordable, plagiarism-free, and on time!

Posted: December 25th, 2024

It is difficult to simulate and complex to describe the interaction of space particles with airborne electronics and materials using ground-based test facilities. Furthermore, it is impossible to fully specify the space radiation environment for a given mission because of unknowns in mapping it and unknowns in the process that generates it. It is also a challenge to completely assess the hazards at any altitude and latitude because the space radiation environment changes with time, often in unpredictable ways.

The majority of the effects of radiation are known and can be experimented with in flight experiments and in developed laboratories. However, it is critical to have the ability to protect air vehicles from radiation to help reduce its risks. The shielding material choice is a major part of the design. Figure 4.1 illustrates the basic radiation shielding process.

We hear “Can you write in APA or MLA?” all the time—and the answer’s a big yes, plus way more! Our writers are wizards with every style—APA, MLA, Harvard, Chicago, Turabian, you name it—delivering flawless formatting tailored to your assignment. Whether it’s a tricky in-text citation or a perfectly styled reference list, they’ve got the skills to make your paper academically spot-on.

The focus of the proceeding experiment demonstrates the effectiveness of different polymer like shielding materials and thicknesses. Among all the types of radiation, this work involved gamma ray and neutron radiation.

This experiment general idea is focused on finding the effectiveness of blocking the ionizing radiation using different materials and thicknesses. The word ionizing refers to the ability to ionize a molecule or an atom of the medium it traverses. Ionizing radiation includes Gamma rays, X-rays and all the atomic and subatomic particles that are available in the space environment such as neutrons, alpha particles, protons, heavy ions, etc. The ionizing radiation can be generally classified into two principle types; one is directly ionizing radiation, which includes radiations of energetic particles carrying an electric charge like alpha particles, protons, beta particles and other recoil nuclei. They cause ionization by direct action on electrons in atoms of the media through which they pass. X-rays, neutrons and Gamma ray photons are classified as indirectly ionizing radiation. These are not charged and they use a more complicated mechanism to cause ionization, involving the emission of energetic secondary particles, which cause most of the ionization [30]. Directly ionizing radiation is easily stopped because it interacts strongly with shielding media. On the other hand, indirectly ionizing radiation may be quite penetrating. Therefore, the shielding required may be expensive and quite massive [30]. Figure 4.2 illustrates the interaction of ionizing radiation with matter.

Initially, many different types of radiation sources were looked at. Alpha, gamma and beta radiation sources are valid options that are prevalent in the space environment. A gamma radiation source was the most plausible because of its higher energy and more occurrences in the space environment. Additionally, in this experiment, attention was given to indirect ionizing radiation. However, obtaining a gamma radiation source that could be used in ground based facilities at an affordable cost proved to be a challenge. Another restriction was safety and ease of obtaining. Because of the long-term dangers of radiation exposure, there are many restrictions on ordering and storing radiation on campus. After some research, a radiation supplier was found.

The radiation source used was a series of radium-226 coated clock hands that emits gamma radiation with a mean particle energy of 0.186 MeV.Ra-226 is a radioactive substance found in nature. In1898, Pierre and Marie Curie discovered radium while conducting research with uranium ore. The radioactive decay of uranium-238 enabled the forming and production of Ra-226. Radioactive decay takes place because certain atoms are unstable and need to release energy in an attempt to become stable. Energy is released when Ra-226 decays in the form of rays (gamma rays) and particles. Our senses cannot detect this energy (radiation) therefore special instrumentation such as Geiger Counters (GCs) is required to perform such detection task.

As mentioned earlier, Geiger Counters are used to measure the dosage of radiation. The Geiger Counter used in this experiment is presented in Figure 4.3.

Prices start at $10 per page for undergrad work and go up to $21 for advanced levels, depending on urgency and any extras you toss in. Deadlines range from a lightning-fast 3 hours to a chill 14 days—plenty of wiggle room there! Plus, if you’re ordering big, you’ll snag 5-10% off, making it easier on your wallet while still getting top-notch quality.

The GC is powered through a USB cable that is connected to a power supply (the switch must be in the ON position). A red light flashes during each bit generation (0 or 1). Each one represents an actual event in the tube in the real time, so the output can be used to deduce the CPM (counts per minutes). A separate computer was programmed using an Arduino board to read the input bit and turn it into an output of the total number of counts in ~60000 milliseconds. An example of the background radiation counts in a total time of ~ 6 min is presented in table 4.1.

| Counts | Time interval (ms) | Total time elapsed (ms) | CPM |

| 11 | 61214 | 78872 | 10.78 |

| 18 | 61233 | 145659 | 17.64 |

| 11 | 60978 | 212158 | 10.82 |

| 15 | 63706 | 297603 | 14.13 |

| 16 | 62942 | 362179 | 15.25 |

The Geiger tube comes with a red boot to protect the end window during production, handling, and shipping. The boot is removedto detect alpha particles. However, in this experiment, our concern is to see activity from gamma radiation. Therefore, the boot was applied during the experiment.

The first consideration in choosing a shielding material must be its effectiveness. A shield is considered effective if it causes a large energy loss in a relatively small penetration distance without emitting more hazardous radiation. Factors that may influence the choice of shielding materials include weight of the material, cost of the material, and how much space is available for the material. The interactions between the incident radiation and the atoms of the absorbing medium determine the effectiveness of the shield. These interactions depend mainly upon the energy of the radiation, the type of the radiation and the atomic number of the absorbing medium. Figure 4.4 shows some radiation shielding materials that are typically used.

Nope—your secret’s locked down tight. We encrypt all your data with top-tier security, and every paper’s crafted fresh just for you, run through originality checks to prove it’s one-of-a-kind. No one—professors, classmates, or anyone—will ever know you teamed up with us, guaranteed.

Many different “plastic like” and carbon based materials have been tested for their effectiveness in radiation shielding. The suitability of these different materials depends not only on whether they are being tested for direct versus indirect radiation, but also on the purpose of the shielding, its duration and the object to be shielded (for example a human being, sensitive electronic equipment, or general equipment). Some properties that may influence material selection in electronic equipment protection include the effectiveness of attenuation (how much radiation it can block either by blocking it or by bouncing the energetic particles through a barrier), material strength, resistance to radiation and mechanical damage, and thermal properties [33].

Some of the advantages of using plastic-like materials and polymers in radiation shielding of electronics include their high hydrogen atom content, low density compared to metals such as lead and aluminum, and the fact that they are solids at room temperature (water, which is also an effective shielding agent, is in liquid form). In addition, polymer-embedded nanostructures are potentially useful for a number of technological applications, especially as advanced functional materials for high-energy radiation shielding and as microwave absorbers. While major interaction processes of these materials at low energies (< 1000 keV) are incoherent or Compton scattering, coherent or Rayleigh scattering and atomic photoelectric effect absorption, the processes at higher energy levels above 1000 keV include nuclear-field pair production and atomic field triplet production [34]. The former group of effects are more important in this case since, as discussed previously, gamma radiation with a mean particle energy of 0.186 MeV was used in this experiment.

The relative dominance of these effects is measured using the gamma-ray mass attenuation coefficient of a material, with photoelectric effects dominating below 1 MeV, Compton scattering at 1 MeV, and pair production above 1 MeV. It has been reported that polyvinyl chloride (PVC) exhibits the highest mass attenuation coefficient value in the energy range 10-110 keV, which is even higher than that of concrete, while another plastic material, Radio Chromic Dye Film, exhibits superior attenuating (shielding) behavior in the range 110-1400 keV [34]. Concrete, which is denser than most plastics, has higher values of total linear attenuation coefficients in the range 10-1400 keV. In comparison, aluminum is not as effective against gamma radiation as lead or concrete [35]. The shielding effectiveness of all materials, however, depends on their densities. As a result, the mass attenuation coefficient may be more important in deciding the shielding effectiveness of a material, and this is the reason that plastic materials may be more effective if adequate thickness is provided for protecting electronic components.

Not even a little—our writers are real-deal experts with degrees, crafting every paper by hand with care and know-how. No AI shortcuts here; it’s all human skill, backed by thorough research and double-checked for uniqueness. You’re getting authentic work that stands out for all the right reasons.

Another issue in assessing the effectiveness of plastic materials as radiation shields is radiation-induced effects, since exposure to radiation causes deleterious effects on properties of many materials. For example, changes in the properties of steels and other metals exposed to high-energy radiation include lower yield stress, tensile strength, hardness, decreased ductility, and toughness. Radiation has similar detrimental effects on the behavior of plastics. For example, both polyethylene (PE) and borated PE have been observed to exhibit significant degradation in terms of thermal and mechanical stability when exposed to continuous irradiation [36].

Three plastic materials were used in the present experiment: Polylactic Acid or polylactide (PLA), Acrylonitrile-Butadiene-Styrene (ABS) and High Impact Polystyrene (HIPS). PLA is a thermoplastic polymer (can be heated to their melting point, cooled, and re-heated again without significant degradation) derived from renewable resource (bioplastic), as opposed to traditional plastics which are derived from the distillation and polymerization of nonrenewable petroleum reserves. The material has several different types including PLLA, PDLLA and PDLA, each has slightly different characteristics. PLA has similar characteristics to polyethylene (PE) and polypropylene (PP). The material production fulfills the dream of cost-efficient as it can be produced from already existing manufacturing equipment like those designed and originally used for petrochemical industry plastics, which makes its production volume the largest of any bioplastic. PLA is commonly available as a 3D printable filament in a myriad of colors. It is one of the two common plastics used in molding manufacturing processes on Fused Deposition Modeling (FDM) machines. ABS is the other common 3D printing plastic. The material is mainly made through two different processes; condensation and polymerization. The usual polymerization technique is known as ring-opening polymerization, which is a process that uses metal catalysts in combined with lactic acid to produce the larger PLA molecules. Condensation process is similar with the main difference being the temperature during the procedure and the condensates released as a result of the reaction [37]. Some of the properties of PLA are shown in Table 4.2 below.

| Property | Value |

| Technical Name | Polylactic Acid (PLA) |

| Chemical Formula | (C3H4O2)n |

| Melt Temperature | 157 – 170 °C (315 – 338 °F) |

| Typical Injection Molding Temperature | 178 – 240 °C (353 – 464 °F) |

| Heat Deflection Temperature (HDT) | 49 – 52 °C (121 – 126 °F) at 0.46 MPa (66 PSI) |

| Tensile Strength | 61 – 66 MPa (8840 – 9500 PSI) |

| Flexural Strength | 48 – 110 MPa (6,950 – 16,000 PSI) |

| Specific Gravity | 1.24 |

ABS is an amorphous polymer and opaque thermoplastic. The material has a strong resistance to corrosive chemicals and physical impacts. Likewise, PLA, ABS is easily machined, and particularly simple for 3D printing and relatively cost effective. Therefore, ABS is being used in a huge number of applications. The material is very structurally robust, which makes it used in things like protective housings, camera housings and packaging. ABS is usually polymerized through the process of emulsion. ABS is also made, although less commonly, by a process called continuous mass polymerization. Generally, the most common methodology to create ABS is through emulsion [38]. Some of the properties of ABS blends are shown in Table 4.3 below.

| Property | Value |

| Technical Name | Acrylonitrile butadiene styrene (ABS) |

| Chemical Formula | (C8H8)x· (C4H6)y·(C3H3N)z) |

| Glass Transition | 105 °C (221 °F) |

| Typical Injection Molding Temperature | 204 – 238 °C (400 – 460 °F) |

| Heat Deflection Temperature (HDT) | 98 °C (208 °F) at 0.46 MPa (66 PSI) |

| Tensile Strength | 46 MPa (6600 PSI) |

| Flexural Strength | 74 MPa (10800 PSI) |

| Specific Gravity | 1.06 |

The polymer HIPS can be manufactured and machined easily at low costs. It is actually a blend of polystyrene and polybutadiene where the latter has a lower concentration (2-8mol %), prepared in such a way that the substance possesses enhanced impact properties. This is ensured by the polybutadiene introduced before the free radical polymerization of styrene – the polybutadiene nodules are then compatibilised by grafting of styrene units so that there is lower degradation of the product [39]. Properties of the polymer are shown in Table 4.4.

Our writers are Ph.D.-level pros who live for nailing the details—think deep research and razor-sharp arguments. We pair that with top plagiarism tools, free revisions to tweak anything you need, and fast turnarounds that don’t skimp on quality. Your research paper won’t just shine—it’ll set the bar.

| Property | Value |

| Technical Name | High Impact Polystyrene (HIPS) |

| Chemical Formula | (C12H16)N |

| Melt Temperature | 210-249 °C (410-480 °F) |

| Typical Injection Molding Temperature | 38 – 66 °C (100 – 150 °F) |

| Heat Deflection Temperature (HDT) | 95 °C (284 °F) at 0.46 MPa (66 PSI) |

| Tensile Strength | 53 MPa (7700 PSI) |

| Flexural Strength | 83 MPa (12000 PSI) |

| Specific Gravity | 1.04 |

As discussed earlier, using a higher density material or increasing the thickness of the shielding material are effective strategies when considering gamma ray shielding for electronic equipment. Therefore, a series of experiments were performed in which each of the materials was used in layers of increasing thickness so that the effective thickness was increased.

The background radiation measured using the Geiger counter in the absence of radiation source or shield is shown in Figure 4.5. The average count per minute (CPM) for background radiation in this case was 13.

The background radiation measured using the Geiger counter with a radiation source but with no shield is shown in Figure 4.6. The average count per minute (CPM) in this case was 451.

You’re in good hands with degree-holding pros—many rocking Master’s or higher—who’ve crushed our tough vetting tests in writing and their fields. They’re your partners in this, hitting tight deadlines and academic standards with ease, all while tailoring every essay to your exact needs. No matter the topic, they’ve got the chops to make it stellar.

Measured CPM values for four materials – ABS (black), PLA (blue), HIPS (red) and ABS+PLA (purple) – are shown in Figure 4.7. The shielding thickness of materials was doubled each time from 2 mm to 4 mm to 8 mm to 16 mm. It can be observed that each doubling of thickness reduces CPM – for example in case of ABS (black line) the averaged CPM value decreased from 265 (2 mm) to 229 (4 mm) to 171 (8 mm). Similarly, in the case of HIPS (red line) the averaged CPM value decreased from 276 (2 mm) to 215 (4 mm) to 166 (8 mm) to as low as 125 (16 mm, shown in the bottom panel). The graphs also show considerable variations in CPM counts over time – in particular, a spike in CPM for HIPS having thickness 2 mm (top panel), indicating ineffectual shielding for that thickness.

However, the considerable overlapping of the black and blue lines in the top three plots indicates that there is no significant difference between ABS and PLA. The bottom graph only shows two materials – HIPS at 16 mm (red) and a combination of two sheets of PLA and ABS of thickness 8 mm each (purple) because, as can be observed in the graphs, although there is no practical difference in shielding ability between ABS and PLA there is some difference in the case of HIPS. It can be observed that increasing the shielding thickness not only reduces CPM for all four materials but also decreases fluctuations. This is desirable for electronic equipment, which may otherwise get damaged from a single, randomly high exposure incident. Some of the variations in CPM observed in these figures can be attributed to fluctuating background radiation events.

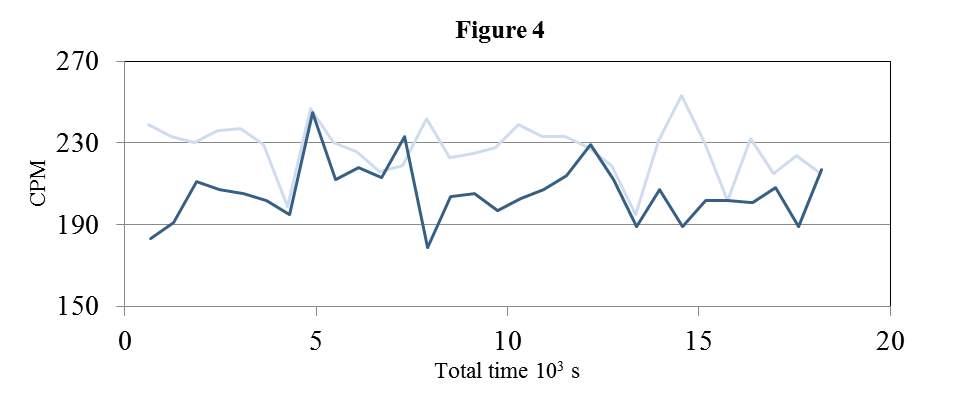

The effectiveness of aluminum as a shielding agent is shown in Figure 4.8. Two different thicknesses are shown, 2 mm and 4 mm, depicted by light blue and dark blue lines respectively. The average CPM for aluminum is lower than for the plastic materials for equivalent thickness – 218 and 203 respectively – suggesting that it is a more effective shielding agent when equivalent thicknesses are used. However, as observed in Figure 4.7 earlier, HIPS and PLA have comparable effectiveness when thicker layers of these materials are used. This suggested that HIPS and PLA, which are more flexible and cost-effective, can be as good (or better) electronic shielding agent as aluminum if higher thickness is used.

The effectiveness of all materials in the experiment is presented in Figure 4.9 in terms of their R values, where R is the ratio of the average CPM for a given material of given thickness and average CPM with no shield (R= CPMavg/CPM0). Therefore, R is a measure of the effectiveness of the material having the specified thickness. A correction was also incorporated in the graph by subtracting the background radiation value of 13 (correction factor = CPMavg – 13) so that the effect of the shielding against Gamma rays could be shown more clearly. A combination of ABS and PLA is shown because it was earlier determined that this pair has a different shielding effectiveness than HIPS.

A comparison of the effectiveness of HIPS and a combination of PLA and ABS against aluminum is presented in Figure 4.10, where it can be observed that aluminum is more effective at 2 mm thickness. At 4 mm the plastics are comparable to aluminum.

The R value calculations at different thickness levels for HIPS, aluminum and PLA and ABS combined are shown in Table 4.5 below.

| Materials | Thickness (mm) | CPMAvg | CPMAvg |

You Want The Best Grades and That’s What We Deliver

Our top essay writers are handpicked for their degree qualification, talent and freelance know-how. Each one brings deep expertise in their chosen subjects and a solid track record in academic writing.

We offer the lowest possible pricing for each research paper while still providing the best writers;no compromise on quality. Our costs are fair and reasonable to college students compared to other custom writing services.

You’ll never get a paper from us with plagiarism or that robotic AI feel. We carefully research, write, cite and check every final draft before sending it your way.