Top Essay Writers

Our top essay writers are handpicked for their degree qualification, talent and freelance know-how. Each one brings deep expertise in their chosen subjects and a solid track record in academic writing.

Simply fill out the order form with your paper’s instructions in a few easy steps. This quick process ensures you’ll be matched with an expert writer who

Can meet your papers' specific grading rubric needs. Find the best write my essay assistance for your assignments- Affordable, plagiarism-free, and on time!

Posted: September 9th, 2024

Table of Contents

We hear “Can you write in APA or MLA?” all the time—and the answer’s a big yes, plus way more! Our writers are wizards with every style—APA, MLA, Harvard, Chicago, Turabian, you name it—delivering flawless formatting tailored to your assignment. Whether it’s a tricky in-text citation or a perfectly styled reference list, they’ve got the skills to make your paper academically spot-on.

Yes, completely! They’re a valid tool for getting sample papers to boost your own writing skills, and there’s nothing shady about that. Use them right—like a study guide or a model to learn from—and they’re a smart, ethical way to level up your grades without breaking any rules.

2.5 Competitors and Market Share

Prices start at $10 per page for undergrad work and go up to $21 for advanced levels, depending on urgency and any extras you toss in. Deadlines range from a lightning-fast 3 hours to a chill 14 days—plenty of wiggle room there! Plus, if you’re ordering big, you’ll snag 5-10% off, making it easier on your wallet while still getting top-notch quality.

Nope—your secret’s locked down tight. We encrypt all your data with top-tier security, and every paper’s crafted fresh just for you, run through originality checks to prove it’s one-of-a-kind. No one—professors, classmates, or anyone—will ever know you teamed up with us, guaranteed.

3.4 Final Location of DME production Facility

Not even a little—our writers are real-deal experts with degrees, crafting every paper by hand with care and know-how. No AI shortcuts here; it’s all human skill, backed by thorough research and double-checked for uniqueness. You’re getting authentic work that stands out for all the right reasons.

4.4 CO2 Hydrogenation to Form Methanol

4.5 Methanol Dehydration to Form Dimethyl Ether

Our writers are Ph.D.-level pros who live for nailing the details—think deep research and razor-sharp arguments. We pair that with top plagiarism tools, free revisions to tweak anything you need, and fast turnarounds that don’t skimp on quality. Your research paper won’t just shine—it’ll set the bar.

5.2 Assumptions and Methodology

You’re in good hands with degree-holding pros—many rocking Master’s or higher—who’ve crushed our tough vetting tests in writing and their fields. They’re your partners in this, hitting tight deadlines and academic standards with ease, all while tailoring every essay to your exact needs. No matter the topic, they’ve got the chops to make it stellar.

5.3 Cost Estimate Classification

6 Social, Environmental, Economic Impacts

100%—we promise! Every paper’s written fresh from scratch—no AI, no copying—just solid research and proper citations from our expert writers. You can even request a plagiarism report to see it’s 95%+ unique, giving you total confidence it’s submission-ready and one-of-a-kind.

Yep—APA, Turabian, IEEE, Chicago, MLA, whatever you throw at us! Our writers nail every detail of your chosen style, matching your guidelines down to the last comma and period. It’s all about making sure your paper fits academic expectations perfectly, no sweat.

Absolutely—life happens, and we’re flexible! Chat with your writer anytime through our system to update details, tweak the focus, or add new requirements, and they’ll pivot fast to keep your paper on point. It’s all about making sure the final draft is exactly what you need, no stress involved.

Commercial production of DME initiated in 1963 by Akzo Nobel for use in aerosol propellants as non-ozone depleting substitute to CFCs (McKone, et al., 2015). With increasing oil prices in the 1970s and 1980s due to numerous embargos, global R&D programs were introduced focusing on the use of DME as an alternative fuel. The first fuel DME project was launched in the late 20th century with a joint venture between oil giant Amoco, the India Oil Company and the Gas Authority of India (McKone, et al., 2015). Soon followed the establishment of various fuel DME associations including the International DME association, the Japan DME Forum and the China DME Association. The early to mid-2000s saw the emergence of China as a dominate force in global DME production. The commercialisation of LPG blending promoted a production capacity increase of 467% from 3Mt in 2007 to 14Mt in 2015 (CCF Group, 2016).

Analysis of the global Dimethyl Ether (DME) market revealed the industry to be worth an estimated USD 5.16 billion in 2015, with significant growth recorded over the last decade (Global Market Insights Inc, 2016). The market share is divided amongst three major regions being the Asian pacific, North America and Europe. The Asian Pacific region, mainly led by China dominates the industry with over 95% market share.

To describe the extent of the role China plays in the DME market, in 2012 China was responsible for consuming more than 90% of the world’s DME, while having a 12 million tonne per year production capacity (CCF Group, 2016). Although the Chinese market posted very strong growth in the 2000s, however recent bans being imposed by the government on LPG blending and a shutdown of illegal blending practices have stifled growth. In turn, this has resulted in an overcapacity of DME and an only 20-30% utilisation rate of production facilities.

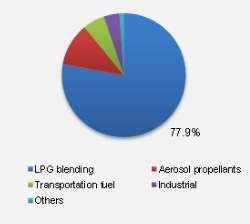

In today’s market, applications of DME can be divided into 4 major categories:

Traditionally, the use of DME in aerosol products including hairsprays and cosmetics has been the most widespread application. However, China who is the world’s largest consumer of LPG have commercialised the use of DME in LPG blending. LPG blending involves the blending of LPG with 20% DME which can be used in domestic households. As of 2013, an estimated 78% of global DME was utilised in LPG blending.

This has greatly benefited China in relying less on LPG imports and also reducing its emission footprint through the introduction a cleaner domestic fuel. Companies in Indonesia, India and Vietnam have expressed desire in implementing LPG blending in their respective countries.

We can crank out a killer paper in 24 hours—quality locked in, no shortcuts. Just set your deadline when you order, and our pros will hustle to deliver, even if you’re racing the clock. Perfect for those last-minute crunches without compromising on the good stuff.

Transportation fuel is a relatively newer DME application venue that is yet to be widely commercialised, however it is believed to be the most promising growth opportunity for the DME market in the future.

DME’s quality ignition and high Cetane number makes it ideal as a low pollutant substitute for diesel fuel in both heavy trucks and passenger vehicles. The benefits of using DME as an alternative to diesel is that existing LPG infrastructure can still be used for the transportation and storage of DME and only minor vehicle modifications will be required.

This adoption of non-petroleum based fuel alternative has been strongly supported by automotive manufacturers, in particular heavy duty truck companies such as Volvo and Mack. These companies are the first in the world to have a commercial DME fuelled truck fleet that is available in the North American market. Additionally, Ford are leading a EUD 3.5 million research project in the development DME fuelled passenger vehicles in collaboration with the German government.

This adoption of non-petroleum based fuel alternative has been strongly supported by automotive manufacturers, in particular heavy duty truck companies such as Volvo and Mack. These companies are the first in the world to have a commercial DME fuelled truck fleet that is available in the North American market. Additionally, Ford are leading a EUD 3.5 million research project in the development DME fuelled passenger vehicles in collaboration with the German government.

With the introduction of stringent environmental regulations and the rising awareness of petroleum fuel pollution, it is projected that the DME market will see enormous growth in the transportation fuel sector in the next decade.

Review of the Australian DME market revealed to be no current DME production facilities operating in Australia (Syed, Nowakowski, Nicholson, & Ahmed, 2014). Even though Australia has Asia’s second largest aerosol products market, DME usage in this industry is relatively small scaled and demand is adequately met by imports from China. Having said that, CSR operated a 10 kt/y DME plant in NSW, Australia in 1988 for aerosol propellant use however this has since been dismantled (Syed, Nowakowski, Nicholson, & Ahmed, 2014).

For sure! Our writers with advanced degrees dive into any topic—think quantum physics or medieval lit—with deep research and clear, sharp writing. They’ll tailor it to your academic level, ensuring it’s thorough yet easy to follow, no matter how tricky the subject gets.

The major challenge facing Australian DME production is the lack of incentives by investors due to very limited application of DME in the Australian fuel market and high cost of producing renewable DME (Gough, 2016). In 2002, Japanese consortium Japan DME planned to build the world’s largest DME plant in the Burrup Peninsula, Western Australia that was expected to produce approximately 1.65 Mt/a. However the project was abandoned a few years later citing the inability to source natural gas at a reasonable cost. Hence, production cost is a major challenge in the implementation of large scale DME production in Australia.

With the small scale use of DME in the aerosol industry and the absence of LPG blending due to Australia’s high LPG capacity, the transportation fuel market is identified as the most attractive option for application in Australia. Australia is one of the world’s largest diesel consumers per capita with over 13.9 billion litres used by the road transportation sector in the 2015/16 financial year. Furthermore, the introduction of DME fuelled heavy duty trucks by Volvo and Mack who own a 25% share of Australia’s heavy duty trucking industry has elevated the prospect of replacing diesel with DME. Therefore, there is a great incentive in the introduction of DME fuelled vehicles in Australia as a lower emission substitute to diesel.

In addition to China, Japan has been recently involved in developing large commercial DME operations such as the Niigata City DME plant which became operational in 2011. Others including Sweden, Iceland, Germany and the US have all invested in small DME production facilities to meet local demands. Although there are only a few countries currently involved in commercial DME production, a very large number are developing plans to build large capacity DME plants. Countries ranging from South Korea, Iran, Egypt, India, Indonesia and Iran have constructed demonstration facilities to test the feasibility for large scale production of DME. Figure below displays the global DME fuel market capacity in 2010 from the 4th International DME Conference in Stockholm.

Chinese manufacturers also dominate the market with around 79 Chinese companies being involved in DME operations. The major DME manufacturers in the world and their target market applications are listed in the table below.

Table 2‑1

| Manufacturer | Country of operation | Target Market |

| Akzo Nobel NV Corporation | Netherlands | Aerosol propellants |

| China Energy Ltd | China | LPG blending/ Aerosol propellants |

| Mitsubishi Corporation | Japan | Industrial and transportation fuel |

| Oberon fuels | USA | Transportation fuel |

| Fuel DME Production Corporation Ltd | Japan | Industrial and transportation fuel |

| Shenhua Ningxia Coal | China | LPG blending |

| Luithianhua Group | China | LPG blending |

| XinAo Group | China | LPG blending |

| Grillo-Werke AG | Germany | Aerosol propellants |

Of the DME producers listed above, China Energy Ltd claims to be the world’s largest manufacturer of DME. Furthermore, USA manufacturer Oberon Fuels is the only current DME producer with a sole focus on transportation fuel use for heavy duty trucks.

Based on an industry research report in 2015, the market size is projected to exhibit a Compounded Annual Growth Rate (CAGR) of 9.9% by 2024. As explained above, the main growth driving force will be the commercialisation of DME as a transportation fuel, predicted to have a CAGR of 14% by 2024.

Send us your draft and tell us your goals—we’ll refine it, tightening arguments and boosting clarity while keeping your unique voice intact. Our editors work fast, delivering pro-level results that make your paper pop, whether it’s a light touch-up or a deeper rework.

This is of particular interest to Australia as one of the world’s largest consumers of diesel. Industry analysis forecast diesel prices to continue elevating in the future and with relatively cheaper DME being available, Australian consumers will be expected to support the use of DME as an alternative. However for the successful implementation of fuel DME, challenges such as production costs and viability of using DME as a diesel alternative need to be carefully considered. It is important to note that in order for DME to have a positive economic effect, production must be considered at a large scale to drive costs down and position fuel DME as a cheaper alternative to diesel.

The next decade could also involve increasing the investment of bio based DME operations. Bio based DME production involves the use of non-fossil fuel produced methanol feedstock and currently, there is only one operational bio based DME plant in the world located in Sweden. With the rising elimination of fossil fuel dependence, the bio based DME market is projected to post significant growth at a CAGR of 11% in the next decade.

Location of the DME plant is one of the key factors in the starting stage of the DME industry. It will greatly affect the profitability and social recognition of the new alternative fuel. Aim of this project is to reduce emission of greenhouse gas, carbon dioxide, from the nature gas production, and transform them into DME. Our targeting market is the diesel used in heavy transporting vehicles within Australia. In 2015, 2863 million litters of diesel were consumed for truck transportation. To replace that, 188 thousand tonnes of DME will be produced each year, which will need about 500 million tonnes of CO2.

Nature gas basins produce nature gas which contains 10% to 30% of CO2, which is the carbon source for this project. Four gas basins were selected and compared in details as long as other location factors.

The DME plant together with the gas conditioning plant should be close to the gas field for it would cost less on building pipes and on-land transporting. It will also reduce the need of pumping and storage facilities.

Yes—we’ve got your back! We’ll brainstorm fresh, workable ideas tailored to your assignment, picking ones that spark interest and fit the scope. You choose the winner, and we’ll turn it into a standout paper that’s all yours.

Land of the plant should be of industry use. It should be far away from main cities, downwind side of residential area and should not be located on heritage sites or other protected places.

This project is not considered to be a labour-intensive initiative. It can create job opportunities in nearby areas. Process engineers, operators and other workers may probably come from neighboring cities. The infrastructure is also an important factor while planning for a new plant. The existing infrastructure in the neighbouring major cities will be preferred, especially for the start-up stage.

Our current target market is transportation fuel blending for trucks. From a long-term perspective, many car manufacturers, such as Ford and Hyundai, are developing new DME fuel cars for higher efficiency and less NOx emission. If these DME fuel cars are largely promoted, they will first appear in modernized cities such as Melbourne, Sydney and Perth. So the DME plant is better to be close to these cities.

Gas producing companies may be very much willing to find opportunities to build by-product plants individually or in a cooperate manner. On one hand, they can reduce the emission of CO2, SO2 and other toxic gases. On the other hand, gas companies can have a good reputation of making less carbon footprint.

Table 3‑1. Comparison of four potential locations and key selection criteria.

| Kipper-Turrum | Ichthys | Gorgon | Curtis | |

| * Capacity of CO2 | 436870.93 | 2600422.222 | 5.5-8.8 million tonnes | 5.75 million tonnes |

| * Purity of CO2 produced | 96%-99% ( gas sweetening) | 96%-99% (gas sweetening) | 99.70% | Pure |

| * Current use of CO2 | immediately vented | not yet | 3.4-4 million injection | emission |

| * Lifetime of gas field production | 10 years | 20-30 years | Ends between 2054-2074 | 24 years life from 2014 |

| * Company image/incentives | Exxon | Inpex Corporation | ||

| * Existing infrastructure | gas conditioning plant | not yet | ||

| * Labour | ||||

| * Price of land | 1million for 2289 m2 | 0.72 million for 336 m2 |

The final decision for the location of this DME plant is using CO2 for the Longford gas conditioning plant of Kipper Tuna Turrum wells in Gippsland basin. The Longford plant is located in Gippsland, together with three gas producing plants. Gippsland is located in Victoria, about 300km east of Melbourne. Kipper Tuna Turrum produce Nature gas containing average 8.5% of CO2. The Longford plant separate CO2 and H2S from the raw gas and present to the DME plant.

CO2 is removed from the Longford gas conditioning plant, the assumption was made that there is also some impurity in the CO2 stream such as hydrogen sulfide (H2S), mercaptans(R-SH), carbonyl(COS) and carbon disulfide (CS2). However, the mercaptans, carbonyl and carbon disulfide is negligible compared to hydrogen sulfide, only H2S removal technologies will be discussed here.

There are two main technologies involved with H2S removal, which is liquid phase process (Claus sulfur scavenger) and dry bed process (Metal Oxide process)

Table 4‑1.

| Technologies | Claus Process | Amine | Membranes | Hot Potassium carbonate | Dry bed process |

| Acid Gas Inlet Content (Volume%) | 0-100% | Up to 70% | Up to 90% | 5~50% | 0.1~2% |

| Advantage | High sulfur recovery | Most widely used. | Small footprint, less than 1% V of acid gas at outlet. | Relatively low operational lost | Process are limited to sulfur removal |

| Disadvantage | Amine solution frequently become contaminated |

You Want The Best Grades and That’s What We Deliver

Our top essay writers are handpicked for their degree qualification, talent and freelance know-how. Each one brings deep expertise in their chosen subjects and a solid track record in academic writing.

We offer the lowest possible pricing for each research paper while still providing the best writers;no compromise on quality. Our costs are fair and reasonable to college students compared to other custom writing services.

You’ll never get a paper from us with plagiarism or that robotic AI feel. We carefully research, write, cite and check every final draft before sending it your way.