Top Essay Writers

Our top essay writers are handpicked for their degree qualification, talent and freelance know-how. Each one brings deep expertise in their chosen subjects and a solid track record in academic writing.

Simply fill out the order form with your paper’s instructions in a few easy steps. This quick process ensures you’ll be matched with an expert writer who

Can meet your papers' specific grading rubric needs. Find the best write my essay assistance for your assignments- Affordable, plagiarism-free, and on time!

Posted: May 23rd, 2024

Aditya Patel

Equipment Utilized

We get a lot of “Can you do MLA or APA?”—and yes, we can! Our writers ace every style—APA, MLA, Turabian, you name it. Tell us your preference, and we’ll format it flawlessly.

An assortment of hand tools, pullers and specialty measuring tools were used during this assignment

Health and Safety Precautions

Safety boots and glasses were mandatory in the shop

Proper lifting techniques, and getting help lifting was very important

Totally! They’re a legit resource for sample papers to guide your work. Use them to learn structure, boost skills, and ace your grades—ethical and within the rules.

Unit Identification

GM 3100 Engine

References

Starts at $10/page for undergrad, up to $21 for pro-level. Deadlines (3 hours to 14 days) and add-ons like VIP support adjust the cost. Discounts kick in at $500+—save more with big orders!

GM 3100 service manual, and our classroom text book were used. Lab notes and internet were used for some of the notes.

Method

1. List all the steps needed to measure cylinder taper and out of round.

Cylinder Taper is the difference of the diameter between top of the cylinder bore under the ridge and bottom of the cylinder

100%! We encrypt everything—your details stay secret. Papers are custom, original, and yours alone, so no one will ever know you used us.

Cylinder out of Round is the difference of diameter when measured parallel to crankshaft and then perpendicular to the same at top of the cylinder using bore gauge.

Method – Continued

2. Document 2 methods of measuring piston to cylinder bore clearance.

Feeler Strip Method

Nope—all human, all the time. Our writers are pros with real degrees, crafting unique papers with expertise AI can’t replicate, checked for originality.

(Measuring clearance using feeler strip)

Calculated Method

Our writers are degree-holding pros who tackle any topic with skill. We ensure quality with top tools and offer revisions—perfect papers, even under pressure.

(Bore gauge measuring the cylinder diameter)

(Measuring piston diameter using Micrometre)

3. Construct a chart listing cylinder, piston ring and crankshaft clearances.

Experts with degrees—many rocking Master’s or higher—who’ve crushed our rigorous tests in their fields and academic writing. They’re student-savvy pros, ready to nail your essay with precision, blending teamwork with you to match your vision perfectly. Whether it’s a tricky topic or a tight deadline, they’ve got the skills to make it shine.

4. Record how to check ring clearances. (side and end)

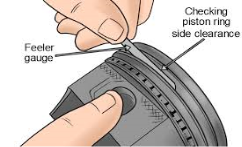

Side Clearance

(Measuring Ring Clearance using Feeler Strip)

Guaranteed—100%! We write every piece from scratch—no AI, no copying—just fresh, well-researched work with proper citations, crafted by real experts. You can grab a plagiarism report to see it’s 95%+ original, giving you total peace of mind it’s one-of-a-kind and ready to impress.

End Gap

If the measured end gap is more then the actual specification the change the ring.

If the measured end gap is more then the actual specification the change the ring.(Measuring piston ring end gap using feeler strip)

5. Describe 2 methods of measuring crankshaft bearing clearance.

Plastigauge Method

Yep—APA, Chicago, Harvard, MLA, Turabian, you name it! Our writers customize every detail to fit your assignment’s needs, ensuring it meets academic standards down to the last footnote or bibliography entry. They’re pros at making your paper look sharp and compliant, no matter the style guide.

Before installing main bearings back, carefully wipe the plastigauge marks.

Before installing main bearings back, carefully wipe the plastigauge marks.(Measuring the Crankshaft bearing clearance using plasti gauge)

Calculated Method

6. Explain what causes cylinder taper and cylinder out of round

Cylinder Taper is caused by wear caused by friction and combustion cause the bore to be cone shaped.

For sure—you’re not locked in! Chat with your writer anytime through our handy system to update instructions, tweak the focus, or toss in new specifics, and they’ll adjust on the fly, even if they’re mid-draft. It’s all about keeping your paper exactly how you want it, hassle-free.

Cylinder Out of Round is caused by pressure created by piston rings to the cylinder walls.

Observations

Cylinder

Measurements |

Cyl #1 |

Cyl #2 |

Cyl #3 |

Cyl #4 |

Cyl #5 |

Cyl #6 |

|

(Thrust Surface – Under Ridge) A How Do I Order a Paper?It’s a breeze—submit your order online with a few clicks, then track progress with drafts as your writer brings it to life. Once it’s ready, download it from your account, review it, and release payment only when you’re totally satisfied—easy, affordable help whenever you need it. Plus, you can reach out to support 24/7 if you’ve got questions along the way! |

0.0016 |

0.0018 |

0.0018 |

0.0015 How Quick Can You Write?Need it fast? We can whip up a top-quality paper in 24 hours—fully researched and polished, no corners cut. Just pick your deadline when you order, and we’ll hustle to make it happen, even for those nail-biting, last-minute turnarounds you didn’t see coming. |

0.0015 |

0.0014 |

|

(Thrust Surface – Bottom) B |

0.0013 |

0.0014 Can You Handle Tough Topics?Absolutely—bring it on! Our writers, many with advanced degrees like Master’s or PhDs, thrive on challenges and dive deep into any subject, from obscure history to cutting-edge science. They’ll craft a standout paper with thorough research and clear writing, tailored to wow your professor. |

0.0012 |

0.0014 |

0.0011 |

0.0013 |

|

(90 ° – Under Ridge) C How Do You Match Professor Expectations?We follow your rubric to a T—structure, evidence, tone. Editors refine it, ensuring it’s polished and ready to impress your prof. |

0.0012 |

0.0015 |

0.0012 |

0.0013 How Do You Edit My Work?Send us your draft and goals—our editors enhance clarity, fix errors, and keep your style. You’ll get a pro-level paper fast. |

0.001 |

0.0011 |

Taper (Subtract “B” from “A”)

Measurements |

Cyl #1 |

Cyl #2 |

Cyl #3 |

Cyl #4 |

Cyl #5 |

Cyl #6 |

|

(Thrust Surface – Under Ridge) A |

0.0016 Can You Brainstorm Topics?Yep! We’ll suggest ideas tailored to your field—engaging and manageable. Pick one, and we’ll build it into a killer paper. |

0.0018 |

0.0018 |

0.0015 |

0.0015 |

0.0014 |

|

(Thrust Surface – Bottom) B |

0.0013 Do You Offer Fast Edits?Yes! Need a quick fix? Our editors can polish your paper in hours—perfect for tight deadlines and top grades. |

0.0014 |

0.0012 |

0.0014 |

0.0011 |

0.0013 |

|

Taper Can You Start With an Outline?Sure! We’ll sketch an outline for your approval first, ensuring the paper’s direction is spot-on before we write. |

0.0003 |

0.0004 |

0.0006 |

0.0001 |

0.0004 |

0.0001 |

|

Specification |

0.0008 Can You Add Charts or Stats?Definitely! Our writers can include data analysis or visuals—charts, graphs—making your paper sharp and evidence-rich. |

——— |

——— |

——— |

——— |

——— |

Out of Round ( Subtract “C” from “A” )

Measurements |

Cyl #1 |

Cyl #2 |

Cyl #3 |

Cyl #4 |

Cyl #5 |

Cyl #6 |

|

( Thrust Surface – Under Ridge ) A |

0.0016 |

0.0018 |

0.0018 What About Multi-Part Projects?We’ve got it—each section delivered on time, cohesive and high-quality. We’ll manage the whole journey for you. |

0.0015 |

0.0015 |

0.0014 |

|

( 90 ° – Under Ridge ) C |

0.0012 Do You Adapt to International Rules?Yes! UK, US, or Aussie standards—we’ll tailor your paper to fit your school’s norms perfectly. |

0.0015 |

0.0012 |

0.0013 |

0.0010 |

0.0011 What does a complex assignment mean?If your assignment needs a writer with some niche know-how, we call it complex. For these, we tap into our pool of narrow-field specialists, who charge a bit more than our standard writers. That means we might add up to 20% to your original order price. Subjects like finance, architecture, engineering, IT, chemistry, physics, and a few others fall into this bucket—you’ll see a little note about it under the discipline field when you’re filling out the form. If you pick “Other” as your discipline, our support team will take a look too. If they think it’s tricky, that same 20% bump might apply. We’ll keep you in the loop either way! |

|

Out of Round |

0.0004 |

0.0003 |

0.0006 Who is my writer? How can I communicate with him/her?Our writers come from all corners of the globe, and we’re picky about who we bring on board. They’ve passed tough tests in English and their subject areas, and we’ve checked their IDs to confirm they’ve got a master’s or PhD. Plus, we run training sessions on formatting and academic writing to keep their skills sharp. You’ll get to chat with your writer through a handy messenger on your personal order page. We’ll shoot you an email when new messages pop up, but it’s a good idea to swing by your page now and then so you don’t miss anything important from them. |

0.0002 |

0.0005 |

0.0003 |

|

Specification |

0.0005 |

——— |

——— |

——— |

——— |

——— |

Observations – Continued

Measurements |

Specs |

#1 |

#2 |

#3 |

#4 |

#5 |

#6 |

|

Ring End Gap: |

|||||||

|

Top Ring |

0.006-0.014 |

0.24 |

0.24 |

0.24 |

0.27 |

0.17 |

0.19 |

|

Second Ring |

0.0197-0.0280 |

0.30 |

0.16 |

0.20 |

0.18 |

0.16 |

0.19 |

|

Ring Groove Clearance: |

|||||||

|

Top Ring |

0.002-0.0033 |

0.002 |

0.0025 |

0.002 |

0.002 |

0.002 |

0.002 |

|

Second Ring |

0.002-0.0035 |

0.002 |

0.002 |

0.0025 |

0.002 |

0.002 |

0.002 |

Checks |

Specs |

#1 |

#2 |

#3 |

#4 |

|

Bearing Bore Dia. (A) |

2.6472 – 2.6502 |

2.649 |

2.652 |

2.648 |

2.650 |

|

Journal Diameter (B) |

2.6473 – 2.6483 |

2.647 |

2.646 |

2.647 |

2.645 |

|

Clearance (A – B) |

0.0008 – 0.0025 |

0.002 |

0.006 |

0.001 |

0.005 |

|

Plastigauge Clearance |

0.0008-0.0025 |

0.0015 |

0.0020 |

0.0010 |

0.0020 |

Conclusions

Upon completing the measurements and visual inspections, I would recommend that due to the excessive wear and out of round cylinder, the cylinder should be bored. While measuring the piston ring clearance we noticed that the piton rings were replaced and were both of same size on one piston.

Tags: 1500 Words Assessment Task, Ace Homework Tutors, Assignment Homework Help & Answers, Bishops Writing BureauYou Want The Best Grades and That’s What We Deliver

Our top essay writers are handpicked for their degree qualification, talent and freelance know-how. Each one brings deep expertise in their chosen subjects and a solid track record in academic writing.

We offer the lowest possible pricing for each research paper while still providing the best writers;no compromise on quality. Our costs are fair and reasonable to college students compared to other custom writing services.

You’ll never get a paper from us with plagiarism or that robotic AI feel. We carefully research, write, cite and check every final draft before sending it your way.