Top Essay Writers

Our top essay writers are handpicked for their degree qualification, talent and freelance know-how. Each one brings deep expertise in their chosen subjects and a solid track record in academic writing.

Simply fill out the order form with your paper’s instructions in a few easy steps. This quick process ensures you’ll be matched with an expert writer who

Can meet your papers' specific grading rubric needs. Find the best write my essay assistance for your assignments- Affordable, plagiarism-free, and on time!

Posted: June 30th, 2020

Charpy Impact Testing

Introduction

We get a lot of “Can you do MLA or APA?”—and yes, we can! Our writers ace every style—APA, MLA, Turabian, you name it. Tell us your preference, and we’ll format it flawlessly.

Charpy impact testing is designed to measure the energy absorbed by a force placed on different materials that allow us to measure the material’s resistance to failure. The amount of energy a material can absorb or “impact energy” allows us to determine the ductile to brittle transition temperature (DBTT) as well as the ductility of the material itself. Usually, the more ductile a material, the more energy it will absorb due to its tendency to resist fracturing. We used the Charpy test because it is not only cost effective, but it is straightforward and simple to use. The test determines impact energy buy staging a swinging pendulum at a certain height then releasing it to strike a sample thus measuring the energy absorbed by comparing the height the pendulum rises after impact to the height from which it was dropped. Our pendulum had a scale that gave the resultant energy on a scale of 150kJ. We tested various materials with different compositions in various thermal conditions to see the effect of temperature on ductility and brittleness.

Results

|

Table 1: Estimated DBTT (°C) |

|

|

Material Are Writing Services Legal?Totally! They’re a legit resource for sample papers to guide your work. Use them to learn structure, boost skills, and ace your grades—ethical and within the rules. |

DBTT |

|

1018 Normalized |

-30 What’s the Price for a Paper?Starts at $10/page for undergrad, up to $21 for pro-level. Deadlines (3 hours to 14 days) and add-ons like VIP support adjust the cost. Discounts kick in at $500+—save more with big orders! |

|

1045 Normalized |

No Transition |

|

1095 Normalized |

-30 Is My Privacy Protected?100%! We encrypt everything—your details stay secret. Papers are custom, original, and yours alone, so no one will ever know you used us. |

|

1045 Cold-Finished |

175 |

|

304 Stainless Steel |

No Transition Is AI Involved in Writing?Nope—all human, all the time. Our writers are pros with real degrees, crafting unique papers with expertise AI can’t replicate, checked for originality. |

|

6061 Aluminum |

No Transition |

|

PVC |

No Transition Why Are You the Best for Research?Our writers are degree-holding pros who tackle any topic with skill. We ensure quality with top tools and offer revisions—perfect papers, even under pressure. |

Table 1 DBTT for Materials

Table 2 Summary of Temperature, Impact Energy, and Fracture Results

Figure 1: Impact energy for 1045 N and 1045 CF vs Temperature

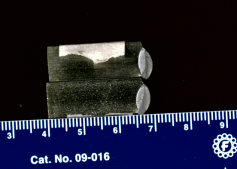

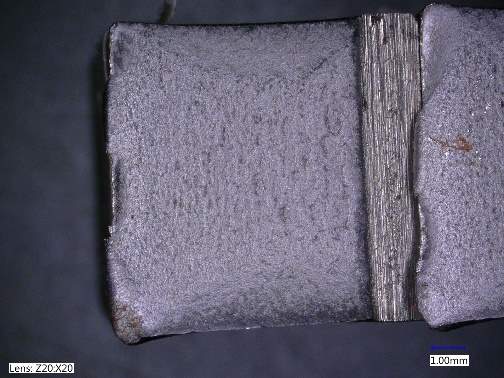

Image 1 1045 CW at 250°C with Camera Image 2 1045 CW at 250°C with 20x Keyence

Guaranteed—100%! We write every piece from scratch—no AI, no copying—just fresh, well-researched work with proper citations, crafted by real experts. You can grab a plagiarism report to see it’s 95%+ original, giving you total peace of mind it’s one-of-a-kind and ready to impress.

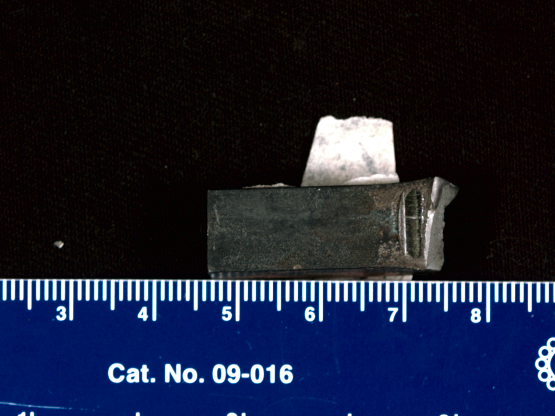

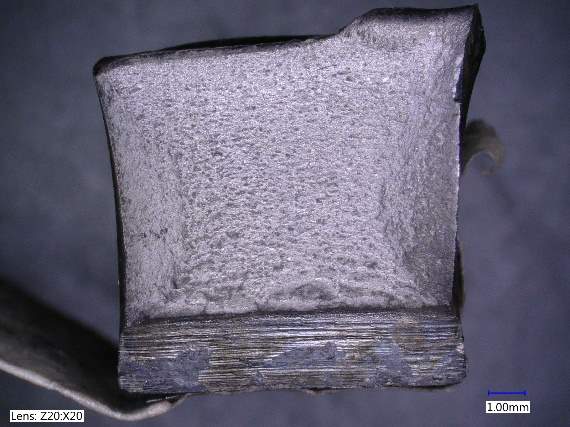

Image 3 1045 Normalized at 250°C with Camera Image 4 1045 Normalized at 250°C with 20x Keyence

Figure 2: Impact energy for PVC, 6061 Al, and 304 SS vs Temperature

Discussion

Yep—APA, Chicago, Harvard, MLA, Turabian, you name it! Our writers customize every detail to fit your assignment’s needs, ensuring it meets academic standards down to the last footnote or bibliography entry. They’re pros at making your paper look sharp and compliant, no matter the style guide.

Figure 1 above shows the difference in impact energy of two 1045 normalized steel versus 1045 cold worked steel at different temperatures. We can clearly see that the 1045 normalized had higher impact strength than the 1045 coldworked. From images 1 and 2 we see that the fracture surface of 1045 CW at 250°C is more ductile than that of the 1045 N. When we look at the raw data; however, we see that the normalized was able to absorb more energy showing that the normalization of the material increased its strength. From Images 1 and 3 we can see that another result of that normalization was an increase in brittleness.

DBTT is the temperature that allows us to calculate where the material changes from brittle to ductile failure [1]. Before DBTT, the 1095 normalized sample was ductile until it reached -60°C as we can see in Table 2. The reading for 1095 at 250 °C is very low at only 2kJ, and does not follow the trend for impact energy for this material, so I believe this to be an error when loading the sample into the impact machine. When comparing the 1045 to the 1018 sample, we can see that while 1018 had higher strength and did not fail from 22°C to 100°C while 1045; however, did even though they are both composed of plain carbon. We did not have a sample for 1018 at 250°C so there is a discrepancy in the data trend at that point. The 1045 cold worked steel became ductile at a much larger temperature than the 1018, and when we look at the composition of 1045 and 1018 we see that it has a larger carbon content. This shows that larger the carbon content, the more brittle the sample [2] When comparing the other plain carbon samples, we see a trend of the impact energy decreasing as percent carbon decreased.

Figure 2 shows the effect of temperature on the impact energy PVC, 6061 Al, and 304 SS. When viewing these results, we have to keep in mind that PVC could not be tested at 250°C or 100°C due to its low melting temperature. From this graph we can clearly see that 304 stainless steel had the best impact strength. From Table 2, the results for impact energy and the viewed fracture surface for each material at its tested temperature clearly show that 304 stainless steel absorbed the majority of the impact energy at all temperatures.

When looking at Figure 2, we see the different impact energies of polyvinyl chloride (PVC), 6061 aluminum alloy aluminum alloy, and 304 stainless steel. The PVC was very brittle especially when tested below room temperature where the sample shattered verses having a smooth brittle failure like the metals. It also has the lowest impact energy than any other material. This explains why we use steel alloys and not PVC in heavy industrial applications. PVC’s strength is very low and it would likely fail if excessive force or weight were to be applied. The 304 stainless steel had the highest impact energy of all other tested materials its composition shows that it less than 0.12% carbon and the rest is mostly chromium, a highly ductile metal. The inclusion of chromium as well as the low percent carbon explains why the stainless steel’s ductility is so high, and why it absorbed the majority of the energy of the force applied by the pendulum.

For sure—you’re not locked in! Chat with your writer anytime through our handy system to update instructions, tweak the focus, or toss in new specifics, and they’ll adjust on the fly, even if they’re mid-draft. It’s all about keeping your paper exactly how you want it, hassle-free.

Conclusion

The Charpy test has allowed us not only to see the impact energy of various materials, but it has explained how composition, temperature, normalization, and cold working affect the strength and ductility of a material. As carbon content increases, we have observed that impact energy increases. The addition of more ductile metals into carbon-based steel alloys for an extremely ductile material which can absorb large amount of energy. With temperature, we saw that with most materials an increase in temperature increased impact energy and ductility, while a decrease led to a sharp decline of impact energy and a large decrease in ductility resulting in brittle failure.

References

You Want The Best Grades and That’s What We Deliver

Our top essay writers are handpicked for their degree qualification, talent and freelance know-how. Each one brings deep expertise in their chosen subjects and a solid track record in academic writing.

We offer the lowest possible pricing for each research paper while still providing the best writers;no compromise on quality. Our costs are fair and reasonable to college students compared to other custom writing services.

You’ll never get a paper from us with plagiarism or that robotic AI feel. We carefully research, write, cite and check every final draft before sending it your way.